The Keeley Halo manual is your gateway to mastering Andy Timmons’ signature dual echo sound. This guide unlocks features, customization, and troubleshooting, ensuring you get the most from your pedal.

1.1 Overview of the Keeley Halo Pedal

The Keeley Halo pedal is a cutting-edge dual echo effects unit designed in collaboration with renowned guitarist Andy Timmons. It combines two independent delay circuits, offering a wide range of tonal possibilities. The pedal features intuitive controls, including Time, Feedback, and Tone knobs, allowing precise shaping of your sound. A High Pass Filter (HPF) is also integrated to refine the feedback loop. The Halo is known for its modulated dual echo sound, which creates a rhythmic, almost reverb-like diffusion. This pedal is versatile, catering to both live performance and studio recording needs. Its compact design houses advanced features like tap tempo functionality and expression pedal compatibility. The Keeley Halo is a testament to Andy Timmons’ signature tone and Robert Keeley’s engineering prowess, making it a must-have for guitarists seeking unique, professional-grade delay effects.

1.2 Importance of the Manual

The Keeley Halo manual is essential for unlocking the pedal’s full potential. It provides detailed instructions for navigating the dual echo functionality, customizing settings, and troubleshooting common issues. Whether you’re a seasoned guitarist or a beginner, the manual ensures you understand how to harness the pedal’s advanced features. It explains the role of each control, such as the Time, Feedback, and Tone knobs, and how they interact to create unique sounds. The manual also covers the High Pass Filter (HPF) and its impact on the feedback loop. By following the guide, users can master the Halo’s modulated dual echo sound, achieve Andy Timmons’ signature tone, and explore the pedal’s versatility. This resource is indispensable for optimizing your musical experience and ensuring you get the most out of your investment in the Keeley Halo pedal.

1.3 Target Audience

The Keeley Halo manual is designed for musicians, particularly guitarists, seeking to master advanced delay and echo effects. It caters to professional players and enthusiasts alike, especially those familiar with Andy Timmons’ signature sound. The manual is ideal for intermediate to advanced users who want to explore the pedal’s dual echo functionality, modulation capabilities, and customization options. It also appeals to sound engineers and tech-savvy musicians interested in understanding the technical aspects of the pedal. Whether you’re a seasoned tone wizard or a player looking to expand your sonic palette, this manual provides the insights needed to unlock the Halo’s full potential. Additionally, it serves as a valuable resource for troubleshooting and maintenance, ensuring optimal performance for years to come. This guide is a must-have for anyone serious about getting the most out of their Keeley Halo pedal.

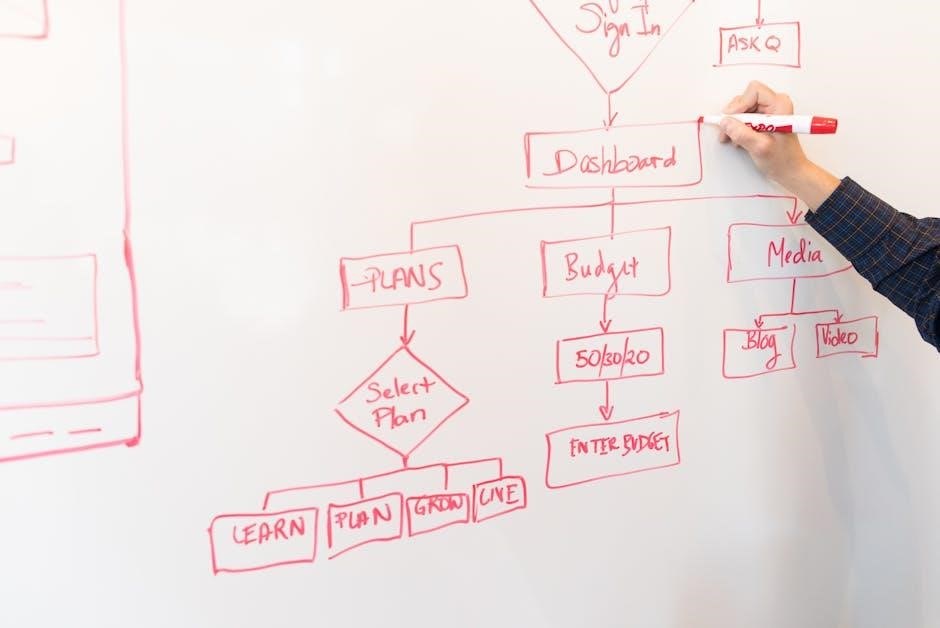

1.4 How to Use This Manual

This manual is structured to guide you through every aspect of the Keeley Halo pedal, from basic operations to advanced features. Start with the introduction to understand the pedal’s overview and importance. The target audience section ensures you identify if this manual is tailored to your needs. Proceed to the features and controls chapter to familiarize yourself with the pedal’s components. The “How to Use the Keeley Halo” section provides step-by-step instructions for basic and advanced operations, including expression pedal usage. Troubleshooting and maintenance sections help resolve common issues and ensure longevity. For deeper understanding, explore the dual echo functionality, collaboration background, and customization options. Advanced features like tap tempo and feedback loops are explained in detail. Use the FAQs and user testimonials for real-world insights. Refer to the index or table of contents to navigate easily. This manual is designed to enhance your experience, so explore it thoroughly to unlock the Halo’s full potential.

Features and Controls of the Keeley Halo

The Keeley Halo features Time, Feedback, Tone, and High Pass Filter controls, each designed to shape and refine your delay sounds with precision and clarity.

2.1 Time Control

The Time control on the Keeley Halo allows you to set the delay length from 1ms to 1500ms. This range offers versatility, from subtle slapback echoes to expansive, ambient soundscapes. Turning the knob clockwise increases the delay time, while counterclockwise decreases it. This control is essential for tailoring the delay to match your musical style, whether you’re playing intricate rhythms or creating lush, atmospheric layers. The Time control works seamlessly with other features like Feedback and Tone to craft unique delay textures. By adjusting this control, you can achieve the perfect balance between clarity and depth in your sound. Experimenting with different settings will help you unlock the full potential of the Halo’s delay capabilities.

2.2 Feedback Control

The Feedback control on the Keeley Halo determines the number of repeats in your delay signal. Turning the knob clockwise increases the feedback, creating more echoes, while counterclockwise reduces it for fewer repeats. This control is crucial for shaping the decay of your delayed sound, allowing you to achieve anything from a single, clean repeat to infinite, ambient loops. When used in conjunction with the Time control, the Feedback knob enables you to craft intricate delay textures. For example, lower feedback settings are ideal for subtle, rhythmic delays, while higher settings can create lush, atmospheric soundscapes. Experimenting with this control will help you find the perfect balance between clarity and complexity in your tone.

2.3 Tone Control

The Tone control on the Keeley Halo adjusts the high-frequency response of the delayed signal, allowing you to shape its brightness and clarity. With a range of 1000Hz to 8750Hz, this control enables you to tailor the tone to suit your playing style and musical context. Turning the knob clockwise increases the high-frequency cutoff, resulting in a brighter, more articulate sound, while counterclockwise reduces it for a warmer, smoother tone. This control is particularly useful for ensuring that the delayed signal complements your guitar’s natural tone without sounding overly harsh or muddy. By fine-tuning the Tone control, you can achieve a balanced blend of clarity and warmth, making your delays sound more cohesive in the mix. Experimenting with this control will help you find the perfect tonal balance for your music.

2.4 High Pass Filter (HPF)

The High Pass Filter (HPF) on the Keeley Halo is a crucial feature that allows you to set the cutoff frequency for the feedback loop, ranging from 10Hz to 300Hz. This control is essential for shaping the low-end response of your delayed signals. By adjusting the HPF, you can remove unwanted low-frequency buildup, ensuring your delays remain clear and defined. Turning the knob clockwise increases the cutoff frequency, allowing more high-frequency content to pass through, while counterclockwise reduces it, preserving lower frequencies. This feature is particularly useful for maintaining clarity in complex musical passages or for creating a tighter, more focused sound. The HPF works in conjunction with the feedback control, enabling you to craft a wide range of tonal textures. Whether you’re playing clean chords or intricate solos, the HPF helps you achieve the perfect balance of depth and articulation in your delay effects.

How to Use the Keeley Halo

Mastering the Keeley Halo involves understanding its intuitive controls and features. Start with basic operations, then explore advanced functions like the expression pedal and tap tempo for precise control over your sound.

3.1 Basic Operations

Mastering the Keeley Halo begins with understanding its core functions. Start by setting the TIME control to adjust delay length from 1ms to 1500ms. Use the FEEDBACK knob to control the number of repeats, creating subtle echoes or infinite loops. The TONE control shapes the delayed signal, allowing you to darken or brighten the sound. Engage the HPF to remove low frequencies in the feedback loop, preventing mud. Press the TAP/HOLD footswitch to set tempo or hold for infinite repeats. For expression pedal users, hold the FDBK knob to enter Expression Mode, enabling external control over parameters. These basic operations form the foundation for crafting unique sounds with the Halo, making it easy to dial in the perfect echo for any musical situation.

3.2 Using the Expression Pedal

The Keeley Halo supports external control via an optional expression pedal, enhancing real-time parameter adjustments. To engage Expression Mode, hold the FDBK knob for 1 second. Once active, the expression pedal can control parameters like TIME, FEEDBACK, or TONE, allowing dynamic, hands-free adjustments during performance. Assign the desired parameter by rotating the corresponding knob while in Expression Mode. This feature adds versatility, enabling seamless transitions and expressive soundscapes. For factory reset, hold the TAP/HOLD footswitch and FDBK knob simultaneously. The expression pedal integration elevates the Halo’s functionality, making it a powerful tool for live musicians and studio artists alike. This section guides you through setup and usage, ensuring you maximize the pedal’s potential.

Troubleshooting Common Issues

Experiencing issues with your Keeley Halo? Start by ensuring proper power supply and connection. If delay isn’t working, check input/output cables and verify pedal placement in your signal chain. For distorted audio, adjust the input level or consult the manual for optimal settings. If the expression pedal isn’t responding, ensure it’s properly calibrated and assigned to the correct parameter. Resetting the pedal to factory settings can resolve unexpected behavior—hold the TAP/HOLD footswitch and FDBK knob simultaneously. For persistent problems, refer to the troubleshooting section in the manual or contact Keeley support. Regular maintenance, like cleaning jacks and updating firmware, can prevent many issues. This guide helps you identify and resolve common problems, ensuring uninterrupted use of your Keeley Halo.

Maintenance and Care

Proper maintenance ensures the Keeley Halo performs optimally. Regularly clean the pedal’s surface with a soft cloth and avoid harsh chemicals. Keep the jacks free from dust and debris by gently brushing them. For stubborn dirt, use a dry contact cleaner. Avoid exposing the pedal to extreme temperatures or moisture, as this can damage internal components. Store the Halo in a protective case when not in use to prevent scratches or damage. Check all cables and connections periodically to ensure they are secure and free from wear. If you notice any unusual noise or malfunction, refer to the troubleshooting section or contact Keeley support. By following these care tips, you’ll extend the life of your Keeley Halo and maintain its exceptional tone and performance.

Understanding the Dual Echo Functionality

The Keeley Halo’s dual echo functionality is its core feature, designed to deliver Andy Timmons’ signature modulated dual echo sound. This innovative design combines two delay engines, allowing for intricate, rhythmic patterns that create a sense of depth and movement. The echoes are enhanced by tape-style effects like modulation, saturation, and compression, which bind the sounds together seamlessly. The feedback control plays a crucial role, enabling you to shape the decay and texture of the echoes. Additionally, the high pass filter in the feedback loop ensures clarity, preventing low-end buildup. This dual echo system is highly versatile, catering to a wide range of musical styles. Whether you’re crafting ambient soundscapes or tight, rhythmic delays, the Halo’s dual echo functionality offers unparalleled control and creativity, making it a standout tool for guitarists seeking unique tonal possibilities.

The Collaboration Between Andy Timmons and Keeley Electronics

The collaboration between Andy Timmons and Keeley Electronics resulted in the creation of the Keeley Halo, a pedal that embodies Andy’s signature modulated dual echo sound. This partnership brought together Andy’s decades of experience in crafting unique delay tones and Robert Keeley’s expertise in pedal design. The Halo is a testament to their shared vision of creating a tool that empowers musicians to achieve exceptional sonic clarity and versatility. Andy Timmons, known for his mysterious and rhythmic delay effects, worked closely with Keeley to ensure the pedal captured his iconic “Halo” sound. Robert Keeley, renowned for his innovative approach to effects, dedicated over three years to refining the design. This collaboration not only honors Andy’s tonal legacy but also sets a new standard for delay pedals in the music industry.

Customization Options

The Keeley Halo offers extensive customization options to tailor the pedal to your unique sound preferences. The High Pass Filter (HPF) allows you to set the cutoff frequency in the feedback loop, ranging from 10Hz to 300Hz, ensuring your delays remain clear and defined. The Tone control adjusts the delayed signal’s frequency response, spanning from 1000Hz to 8750Hz, enabling precise tonal shaping. Additionally, the Expression Pedal provides real-time control over parameters like delay time or feedback, offering dynamic performance flexibility. Users can also customize the pedal’s behavior through the Factory Reset option, restoring default settings for a fresh start. These features empower musicians to craft a sound that is truly their own, making the Halo a versatile tool for both live performances and studio recordings. The customization options ensure that the pedal adapts to your creative vision, delivering unparalleled sonic versatility.

Advanced Features

The Keeley Halo features advanced options like Tap Tempo for precise delay timing and Feedback Loop for adding depth. These tools enhance versatility, offering precise control and rich sonic possibilities.

9.1 Tap Tempo Function

The Tap Tempo function on the Keeley Halo allows for precise control over delay timing. By pressing the Tap Tempo footswitch, you can set the delay time to match your playing tempo. This feature is especially useful during live performances, where maintaining a consistent rhythm is crucial. The Tap Tempo function ensures that your delays are perfectly synchronized with your music, providing a professional and polished sound. Additionally, this feature enhances the overall versatility of the pedal, making it adaptable to various musical genres and styles. With the Tap Tempo, you can achieve dynamic and expressive delay effects that elevate your guitar playing to new heights.

9.2 Feedback Loop Options

The Keeley Halo features a robust feedback loop system, allowing for extensive control over delay repetitions. The Feedback Control (FDBK) knob adjusts the number of repeats in the feedback loop, enabling everything from subtle, natural echoes to chaotic, experimental soundscapes. This feature is particularly useful for creating ambient textures or adding depth to your guitar tone. The feedback loop can also be fine-tuned using the High Pass Filter (HPF), which reduces low-frequency buildup and prevents the sound from becoming muddy. Additionally, the manual explains how to engage the feedback loop in various modes, including infinite repeats when the FDBK knob is turned fully clockwise. This versatility makes the Halo an indispensable tool for both live performances and studio recordings, offering endless possibilities for creative expression and tonal exploration.

High Pass Filter (HPF) Explained

The High Pass Filter (HPF) on the Keeley Halo is a crucial feature that refines your delay sound by setting a cutoff frequency in the feedback loop. This filter ranges from 10Hz at full counterclockwise to 300Hz at full clockwise, allowing you to remove unwanted low-frequency buildup. By adjusting the HPF, you can achieve a cleaner, more defined echo that cuts through the mix without muddying your tone.

Using the HPF effectively prevents low-end frequencies from overwhelming the delay repetitions, ensuring clarity even with complex or layered sounds. This feature is especially beneficial for maintaining a polished sound in both live and studio settings, making the Halo a versatile tool for musicians seeking precision and control over their delay effects.

Tone Controls and Their Impact

The Tone control on the Keeley Halo allows you to shape the frequency response of the delayed signal, ensuring it complements your guitar tone perfectly. This control adjusts the cutoff frequency of the delayed signal, ranging from 1000Hz at full counterclockwise to 8750Hz at full clockwise. By tweaking this knob, you can darken or brighten the repeats, tailoring them to your musical needs.

A lower Tone setting produces warmer, more mellow echoes, while a higher setting yields brighter, more articulate delays. This feature is particularly useful for matching the Halo’s sound to your guitar and amp setup or for creating distinct tonal textures in your music. The Tone control works in harmony with the HPF and Feedback controls, enabling precise sculpting of your delay sound for a wide range of musical applications.

Factory Reset and Expression Pedal Setup

To restore the Keeley Halo to its default settings, perform a factory reset by holding the TAP/HOLD footswitch while powering on the pedal. This will reset all parameters to their original configuration, ensuring a clean slate for your tone-shaping journey.

The Expression Pedal Setup allows for advanced control over the Halo’s features. By entering Expression Mode—accessed by holding the FDBK knob for 1 second—you can assign parameters like Time or Feedback to an external expression pedal. This enables real-time, dynamic adjustments during performance, enhancing your creative expression. The mini toggle can also be used to advance through settings, providing flexibility in how you customize your sound. This feature is ideal for musicians seeking precise control and versatility in their delay effects.

User Testimonials and Reviews

Users and professional musicians alike have praised the Keeley Halo for its versatility and tone-shaping capabilities. Many highlight its ability to deliver Andy Timmons’ signature modulated dual echo sound with ease. Guitarists appreciate the intuitive controls and the depth of customization offered by the pedal. The Expression Pedal Setup has been particularly well-received, allowing for dynamic, real-time adjustments during performances. One user noted, “The Halo has become my go-to delay pedal—it’s the only one I need on my board.” Another praised its “rich, immersive soundscapes” and “seamless integration with other effects.” The collaboration between Andy Timmons and Keeley Electronics has been celebrated, with many calling it a game-changer for delay enthusiasts. Overall, the Keeley Halo has earned a reputation as a must-have tool for musicians seeking professional-grade delay effects.

Frequently Asked Questions (FAQs)

Q: How do I achieve Andy Timmons’ signature Halo sound?

A: Use the dual echo functionality and modulated delay settings as outlined in the manual. Adjust the Time, Feedback, and Tone controls to match his tone.

Q: What is the purpose of the High Pass Filter (HPF)?

A: The HPF reduces low-frequency buildup in the feedback loop, ensuring clarity in your delay repetitions. Adjust it to suit your desired tone.

Q: Can I customize the Tone control?

A: Yes, the Tone control allows you to shape the delayed signal’s high-frequency response, from 1000Hz to 8750Hz, enabling precise tonal adjustments.

Q: How do I perform a factory reset?

A: Hold the TAP/HOLD footswitch while powering on the pedal. This restores all settings to their default configuration.

Q: Is the expression pedal optional?

A: Yes, the expression pedal is optional but recommended for dynamic control over parameters like delay time or feedback during performances.

Conclusion

The Keeley Halo manual serves as a comprehensive guide to unlocking the full potential of this innovative dual echo pedal. Designed in collaboration with Andy Timmons, the Halo offers a unique blend of signature tones and customizable features. By following the manual, users can master the pedal’s advanced functionalities, including the dual echo mode, high pass filter, and tone controls. The manual also provides essential troubleshooting tips and maintenance advice to ensure optimal performance. Whether you’re a seasoned musician or a beginner, this guide equips you with the knowledge to craft your sound with precision. With its clear instructions and detailed explanations, the Keeley Halo manual is an indispensable resource for anyone seeking to elevate their music with this exceptional pedal.